Polyester is a popular garment choice for its durability, wrinkle resistance, and vibrant colors. However, screen printers know it can present a unique challenge: dye migration. This is when the garment’s dye bleeds into the ink, causing a distorted or discolored print. But fear not, fellow printers! By understanding the science behind dye migration and implementing some key strategies, you can achieve stunning, long-lasting prints on polyester garments.

What is Dye Migration and Why Does it Happen?

Imagine tiny dye molecules clinging to the polyester fibers like Christmas ornaments on a tree. When heated to a specific temperature (usually between 260°F and 340°F), these dye molecules transform from a solid to a gas. This process is called sublimation. Now, picture the ink sitting on top of the fabric like a thin layer of paint. If the temperature gets too high, or the heat exposure lasts too long, those gasified dye molecules can sneak into the ink, causing discoloration.

Why is Polyester Prone to Dye Migration?

Unlike natural fibers like cotton, which absorb dye, polyester is hydrophobic, meaning it repels water and dye. Dyes for polyester garments are specially formulated to adhere to the fiber surface. However, that surface bond weakens under high heat, allowing the dye to sublimate and potentially migrate.

The Signs of Dye Migration

Dye migration can show itself in a few ways:

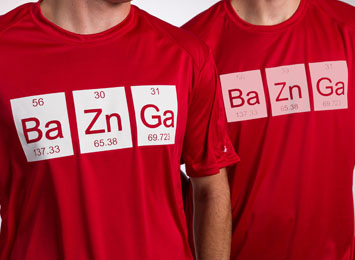

- Color Bleeding: The most common sign is the garment’s dye bleeding into the printed design, creating a hazy or discolored appearance.

- Halo Effect: A faint outline of the garment’s dye color around the edges of the print.

- Print Discoloration: Over time, the print itself may become dull or faded due to dye contamination.

Preventing Dye Migration: Your Printing Arsenal

Now that we understand the enemy, let’s explore the weapons in your screen printing arsenal to combat dye migration:

- Low-Bleed Inks: These inks are specially formulated with minimal dye migration potential. Ask your ink supplier for recommendations on low-bleed inks specifically designed for polyester fabrics.

- Proper Curing: Heat is essential for curing plastisol ink, but it’s a double-edged sword. Here’s the key: use the lowest possible temperature and shortest curing time recommended by your ink manufacturer. Exceeding these recommendations is a recipe for dye migration.

- Pre-Shrinking Garments: Some polyester garments may shrink slightly during the curing process. Pre-shrinking removes this shrinkage potential and ensures the fabric is stable during printing, minimizing dye movement.

- Test Prints: Before printing a large batch, always do a test print on a scrap of the same fabric you’ll be using for the final job. This allows you to fine-tune your curing process and ensure minimal dye migration.

- Wash Test: After completing the test print, wash and dry it according to the garment care instructions. This will reveal any potential dye migration issues that might not be immediately apparent.

- Printing Techniques For light-colored polyesters, using a discharge ink can be an option. Discharge ink works by chemically discharging the existing garment dye, creating a clear canvas for your design. However, this technique requires specific expertise and may not be suitable for all projects.

Beyond Ink and Heat: Fabrics and Communication

- Fabric Choice: Not all polyesters are created equal. Some manufacturers offer high-quality, low-dye migration polyesters specifically designed for screen printing. Consider suggesting these options to your clients who prioritize vibrant, long-lasting prints.

- Client Communication: Open communication is key. Inform your clients about the potential for dye migration on polyester garments, especially with darker colored fabrics. Offer them a variety of fabric options and explain the pros and cons of each. Let them know you’ll be implementing strategies to minimize the risk.

By understanding the science behind dye migration and employing these preventive measures, you can conquer this challenge and produce stunning, long-lasting prints on polyester garments. Remember, a little extra planning and communication go a long way in keeping your clients happy and your prints looking sharp.